The Ultimate Guide To Stahl Specialty Company

Table of ContentsThe 2-Minute Rule for Stahl Specialty CompanyAn Unbiased View of Stahl Specialty CompanyTop Guidelines Of Stahl Specialty CompanyStahl Specialty Company Can Be Fun For AnyoneOur Stahl Specialty Company Statements

The subtle distinction hinges on the chemical content. Chemical Comparison of Cast Aluminum Alloys Silicon advertises castability by decreasing the alloy's melting temperature and improving fluidity throughout casting. It plays an important function in allowing detailed mold and mildews to be filled up precisely. In addition, silicon adds to the alloy's toughness and use resistance, making it valuable in applications where resilience is vital, such as vehicle parts and engine elements.It likewise enhances the machinability of the alloy, making it less complicated to refine into ended up products. This way, iron adds to the overall workability of light weight aluminum alloys. Copper boosts electric conductivity, making it beneficial in electrical applications. It also boosts rust resistance and includes in the alloy's general toughness.

Manganese contributes to the toughness of aluminum alloys and enhances workability. Magnesium is a lightweight component that provides toughness and influence resistance to aluminum alloys.

Zinc boosts the castability of aluminum alloys and aids control the solidification procedure throughout casting. It enhances the alloy's strength and hardness.

How Stahl Specialty Company can Save You Time, Stress, and Money.

Because aluminum-silicon alloys have great casting homes, high gas homes, easy processes, and exceptional rust resistance, aluminum-silicon alloys are most frequently used in the die-casting market at home and abroad. At the exact same time, aluminum-silicon alloys are likewise reasonably very early and commonly identified alloys developed and utilized in die-casting. After constant research study and renovation, the majority of the existing global mainstream aluminum-silicon alloys have actually been wrapped up and are absolutely nothing more than A356, A360, A380, ADC12, B390, and A413.

The primary thermal conductivity, tensile toughness, yield stamina, and elongation differ. Amongst the above alloys, A356 has the greatest thermal conductivity, and A380 and ADC12 have the most affordable.

What Does Stahl Specialty Company Do?

In accuracy spreading, 6063 is fit for applications where complex geometries and high-grade surface finishes are extremely important. Examples include telecommunication units, where the alloy's remarkable formability enables for smooth and cosmetically pleasing styles while keeping structural honesty. In the Lights Solutions industry, precision-cast 6063 elements produce elegant and reliable lights components that require complex shapes and great thermal performance.

(https://www.ted.com/profiles/48419263/about)

The A360 exhibits premium elongation, making it excellent for facility and thin-walled parts. In accuracy casting applications, A360 is well-suited for markets such as Customer Electronics, Telecommunication, and Power Devices.

In accuracy spreading, light weight aluminum 413 radiates in the Consumer Electronic Devices and Power Tools markets. It's typically made use of to craft complex components like smart device housings, video camera bodies, and power tool cases. Its precision is amazing, with tight resistances approximately 0.01 mm, ensuring perfect product assembly. This alloy's superior corrosion resistance makes it a superb choice for exterior applications, guaranteeing durable, resilient items in the mentioned markets.

The Single Strategy To Use For Stahl Specialty Company

Once you have actually chosen that the aluminum die casting procedure appropriates for your job, an important next action is selecting one of the most appropriate alloy. The aluminum alloy you pick will considerably influence both the casting process and see the buildings of the last product. As a result of this, you should make your decision meticulously and take an educated approach.

Establishing the most suitable light weight aluminum alloy for your application will imply weighing a vast range of features. These comparative alloy attributes adhere to the North American Pass Away Casting Organization's guidelines, and we have actually divided them right into 2 classifications. aluminum metal casting. The initial category addresses alloy features that affect the manufacturing process. The 2nd covers qualities influencing the homes of the final product.

The alloy you select for die casting directly affects numerous facets of the spreading procedure, like how easy the alloy is to deal with and if it is vulnerable to casting defects. Hot fracturing, additionally called solidification splitting, is a typical die spreading defect for aluminum alloys that can lead to inner or surface-level rips or cracks.

Stahl Specialty Company Fundamentals Explained

Specific aluminum alloys are much more vulnerable to hot breaking than others, and your selection should consider this. Another usual issue located in the die casting of aluminum is die soldering, which is when the cast stays with the die wall surfaces and makes ejection difficult. It can damage both the cast and the die, so you should try to find alloys with high anti-soldering buildings.

Corrosion resistance, which is already a notable quality of light weight aluminum, can differ considerably from alloy to alloy and is a vital particular to think about depending on the ecological conditions your item will certainly be exposed to. Put on resistance is one more home commonly looked for in aluminum items and can differentiate some alloys.

Haley Joel Osment Then & Now!

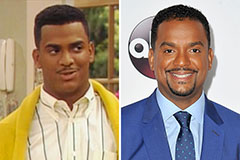

Haley Joel Osment Then & Now! Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!